VERTICAL MACHINING CENTER

Haas VF-6SS with TRT310

High-Performance Super-Speed Large Format VMC

Technical Specifications

Axis Travel (X × Y × Z)

30" × 20" × 20" (762 × 508 × 508 mm)

Spindle

Speed: 12,000 RPM inline direct-drive

Power: 30 HP vector drive

Torque: 90 ft-lb @ 2000 RPM

Taper: CAT-40 or BT-40

Power: 30 HP vector drive

Torque: 90 ft-lb @ 2000 RPM

Taper: CAT-40 or BT-40

Table

Size: 36" × 18" (914 × 457 mm)

Load Capacity: 1,500 lbs

T-Slots: 3 slots, 5/8" wide, 4.92" spacing

Load Capacity: 1,500 lbs

T-Slots: 3 slots, 5/8" wide, 4.92" spacing

Tool Changer

Ultra-fast 24+1 side-mount ATC

Tool-to-Tool: 1.6 sec (avg)

Chip-to-Chip: 2.2 sec (avg)

Max Tool Weight: 12 lbs

Tool-to-Tool: 1.6 sec (avg)

Chip-to-Chip: 2.2 sec (avg)

Max Tool Weight: 12 lbs

Rapids & Feeds

Rapid Traverse: High-speed rapids

Cutting Feedrate: 0.1 – 833 IPM

Cutting Feedrate: 0.1 – 833 IPM

TRT310 Rotary Table

4th-axis capability for multi-sided machining

Ideal for complex geometries and reduced setups

Ideal for complex geometries and reduced setups

Key Capabilities

- Large work envelope for bigger parts and multiple setups

- Super-Speed technology for reduced cycle times

- 4th-axis rotary table for complex multi-sided operations

- High-speed spindle ideal for aluminum and non-ferrous materials

- Inline direct-drive spindle for superior surface finishes

VERTICAL MACHINING CENTER

Haas VF-5SS

High-Performance Super-Speed Mid-Size VMC

Technical Specifications

Axis Travel (X × Y × Z)

50" × 26" × 25" (1270 × 660 × 635 mm)

Spindle

Speed: 12,000 RPM inline direct-drive

Power: 30 HP vector drive

Torque: 75 ft-lb @ 2100 RPM

Taper: CAT-40

Power: 30 HP vector drive

Torque: 75 ft-lb @ 2100 RPM

Taper: CAT-40

Table

Size: 52" × 23" (1321 × 584 mm)

Load Capacity: 1,750 lbs

Load Capacity: 1,750 lbs

Tool Changer

30+1 high-speed side-mount ATC

Tool-to-Tool: 1.6 sec (avg)

Max Tool Weight: 12 lbs

Tool-to-Tool: 1.6 sec (avg)

Max Tool Weight: 12 lbs

Rapids

1,200 IPM (30.5 m/min)

Key Capabilities

- Extended X-axis travel for longer workpieces

- Super-Speed design for high-volume production

- Ideal for aerospace and automotive components

- Fast rapids and quick tool changes reduce cycle time

- Large table capacity for multiple part setups

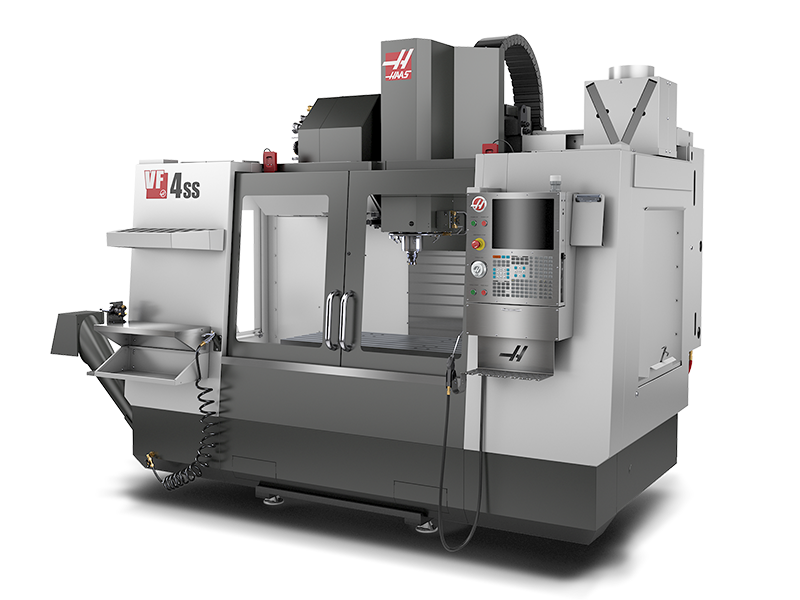

VERTICAL MACHINING CENTER

Haas VF-4SS

High-Speed Super-Speed Production VMC

Technical Specifications

Axis Travel (X × Y × Z)

50" × 20" × 25" (1270 × 508 × 635 mm)

Spindle

Speed: 12,000 RPM inline direct-drive

Power: 30 HP vector drive

Torque: 90 ft-lb @ 2000 RPM

Taper: CAT-40

Power: 30 HP vector drive

Torque: 90 ft-lb @ 2000 RPM

Taper: CAT-40

Table

Size: 52" × 18" (1321 × 457 mm)

Load Capacity: 1,750 lbs

T-Slots: 5 slots

Load Capacity: 1,750 lbs

T-Slots: 5 slots

Tool Changer

24+1 side-mount ATC (30+1 optional)

Tool-to-Tool: 1.6 sec

Chip-to-Chip: 2.2 sec

Max Tool Weight: 12 lbs

Tool-to-Tool: 1.6 sec

Chip-to-Chip: 2.2 sec

Max Tool Weight: 12 lbs

Rapids & Feeds

Rapid Traverse: 1,400 IPM (35.6 m/min)

Cutting Feedrate: 0.1 – 833 IPM

Cutting Feedrate: 0.1 – 833 IPM

Positioning Accuracy

Positioning: ±0.0002"

Repeatability: ±0.0001"

Repeatability: ±0.0001"

Key Capabilities

- Perfect balance of work envelope and speed

- Super-Speed technology for production efficiency

- Extended X-axis for longer parts

- Rigid tapping and high-speed contouring

- Excellent for medical, aerospace, and precision parts

5-AXIS UNIVERSAL MACHINING CENTER

Haas UMC-750SS

Super-Speed 5-Axis Universal Machining Center with Integrated Trunnion

Technical Specifications

Axis Travel (X × Y × Z)

30" × 20" × 20" (762 × 508 × 508 mm)

Spindle

Speed: 15,000 RPM

Power: 30 HP vector drive

Torque: 90 ft-lb @ 2000 RPM

Taper: CAT-40

Power: 30 HP vector drive

Torque: 90 ft-lb @ 2000 RPM

Taper: CAT-40

Trunnion Table

Diameter: 500 mm (19.7")

B-Axis Tilt: +120° / -35°

C-Axis Rotation: 360° continuous

Table Load: 661 lbs (300 kg)

Features: Standard T-slots, integrated high-speed dual-axis

B-Axis Tilt: +120° / -35°

C-Axis Rotation: 360° continuous

Table Load: 661 lbs (300 kg)

Features: Standard T-slots, integrated high-speed dual-axis

Tool Changer

40+1 side-mount ATC

Tool-to-Tool: 2.3 sec

Chip-to-Chip: 3.2 sec

Max Tool Weight: CAT-40 standard

Tool-to-Tool: 2.3 sec

Chip-to-Chip: 3.2 sec

Max Tool Weight: CAT-40 standard

Rapids & Feeds

Linear Axes Rapids: 1,200 IPM (30.5 m/min)

Cutting Feedrate: 650 IPM (16.5 m/min)

Rotary Axes Rapids: 150°/sec (B & C axes)

Cutting Feedrate: 650 IPM (16.5 m/min)

Rotary Axes Rapids: 150°/sec (B & C axes)

5-Axis Capability

Simultaneous 5-axis machining for complex geometries

Full 3+2 positional capability

Continuous 5-axis contouring

Full 3+2 positional capability

Continuous 5-axis contouring

Key Capabilities

- True 5-axis simultaneous machining eliminates multiple setups

- Integrated trunnion table for superior rigidity and accuracy

- 15,000 RPM spindle ideal for complex aerospace and medical parts

- 3+2 indexed positioning and continuous 5-axis contouring

- Reduced cycle times through improved tool access

- Superior surface finishes on complex contoured surfaces

- Optimal for turbine blades, impellers, and organic shapes

CNC TURNING CENTER

Haas ST-30Y

Y-Axis CNC Lathe with Live Tooling & C-Axis

Technical Specifications

Capacity

Max Capacity: 13.75" × 32.5"

Swing: 31.75" (806 mm)

Max Turning Diameter: 18"

Max Turning Length: 23"

Bar Capacity: 3.0" (76 mm)

Swing: 31.75" (806 mm)

Max Turning Diameter: 18"

Max Turning Length: 23"

Bar Capacity: 3.0" (76 mm)

Axis Travel

X-Travel: 12.50" (318 mm)

Z-Travel: 23.00" (584 mm)

Y-Travel: ±2.00" (±50.8 mm)

Z-Travel: 23.00" (584 mm)

Y-Travel: ±2.00" (±50.8 mm)

Spindle

Speed: 3,400 RPM

Power: 30 HP (22.4 kW) vector drive

Spindle Bore: 3.5"

Spindle Nose: A2-6

Power: 30 HP (22.4 kW) vector drive

Spindle Bore: 3.5"

Spindle Nose: A2-6

Turret & Tooling

Turret: 12-station BMT-65

Live Tooling: High-torque with C-axis

Live Tool RPM: 6,000 max

Chuck Size: 10" (254 mm)

Live Tooling: High-torque with C-axis

Live Tool RPM: 6,000 max

Chuck Size: 10" (254 mm)

Accuracy

Positioning: ±0.0002"

Repeatability: ±0.00008"

Repeatability: ±0.00008"

Key Capabilities

- Y-axis milling eliminates secondary operations

- Off-center drilling, milling, and tapping capability

- Complex geometries completed in single setup

- C-axis indexing for full 360° positioning

- Live tooling for mill-turn operations

- Superior tolerance control and surface finishes

- Ideal for shafts, bushings, and complex turned parts